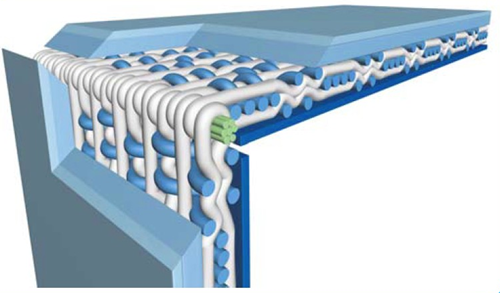

Seamed papermaking felt series

Application scope: all kinds of packaging paper, printing paper, and pulp paper

PM Speed: within 1200 M/MIN

The benefits of using seamed-type products are as following:

- Safety

- Seamed felts use the seaming device on the machine

- No need to move any roller of the papermaking machine and fixed supporting device

- Avoiding safety hazards arising from conventional felts

- Easy cleaning which is superior to ring papermaking felts

- Stable dewatering structure and extended useful life

- High Efficiency

- The replacement time for one piece of felt can be controlled within 2 hours, which is much less than the ordinary 4-6 hours

- Saving labor force

- Enhance the speed in reaching the normal operating status

- High cost-effectiveness and decreasing consumption per ton of paper